What is Plastic Injection Molding?

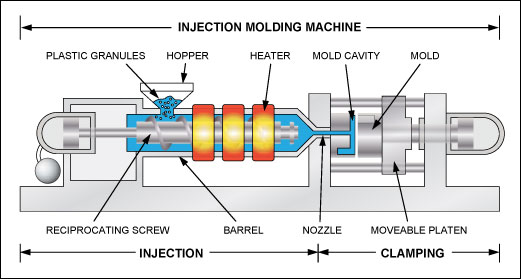

Plastic Injection molding is the manufacturing process of heating plastic granules and forcing the melted plastic into a mold cavity.

What is the Process of Plastic Injection Molding?

Injection molding uses a ram or screw-type plunger to force plastic granules into a mold cavity. This solidifies into a shape that has conformed to the contour of the mold. Injection molding consists of high pressure injection of raw material into a mold which shapes the plastic into the desired shape. Molds can be of a single cavity or may consist of multiple cavities. In multiple cavity molds, each cavity may be identical and form the same parts or it may be unique and form multiple different geometries. Plastic material is fed through a hopper into a heated barrel with a reciprocating screw. Upon entrance to the barrel, the temperature increases and the plastic flows with the driving force of the injection unit. The screw advances the raw material forward and mixes the plastic. The material feeds forward through a check valve and collects at the front of the screw into the shot. A shot is the volume of material that is used to fill the mold cavity, compensate for shrinkage, and provide a cushion.When enough material has gathered, it is forced at high pressure into the cavity. Once the screw reaches the transfer position, the packing pressure is applied which completes the mold being filled. The packing pressure is applied until the gate solidifies and once this happens, no more material can enter the cavity. After this step in the process, the screw reciprocates and acquires material for the next cycle while the material cools. Once the required temperature has been achieved, the mold opens to release the part. After this process, the mold closes and the process is repeated.