A well-managed manufacturing process begins with all potential flaws being determined and addressed prior to the production of the final part.

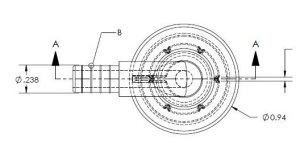

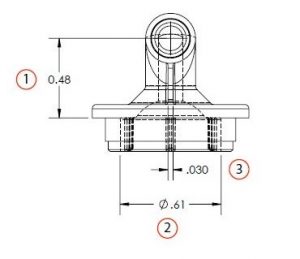

Mold Design -Utilizing mold flow analysis and 3D printed parts, we are able to analyze each part for moldability and product performance.

3-D Printer for Prototyping – Take the guesswork out of your new part design by having us print a part prior to the construction of the mold. Our engineering staff is able to analyze and recommend the most cost effective mold design for your project.

Mold Flow Analysis – Our engineering department has software that will simulate the injection molding process, optimizing product design and manufacturing ability.

On Site Mold Repair and Maintenance – Our onsite toolmakers ensure mold quality by maintaining, repairing and cleaning all molds.

Secondary Operations – We offer comprehensive secondary operations such as hot plate welding, ultrasonic welding, induction welding, heat staking, riveting, solvent bonding, and assembly. As a contract manufacturer, we can provide a wide assortment of assembly solutions from cellular manufacturing to secondary operations.

Superior Customer Service – Our dedicated employees are the reason why Vision Plastics has seen continued growth and expansion. Each employee’s dedication to our customers allows us to produce and deliver cost-effective, high-quality parts on time and in budget. We will achieve customer satisfaction by continually improving processes, products and services to ensure we consistently meet or exceed our customers expectations and requirements.